Related Jobs

View all jobsManufacturing Engineer

Injection Moulding Technical Manager

Shift Supervisor

Senior Machine Learning Engineer

Senior Machine Learning Engineer

Subscribe to Future Tech Insights for the latest jobs & insights, direct to your inbox.

Industry Insights

Discover insightful articles, industry insights, expert tips, and curated resources.

Robotics Jobs for Career Switchers in Their 30s, 40s & 50s (UK Reality Check)

Robotics looks futuristic from the outside. People picture humanoid machines, cutting-edge labs & young engineers writing complex code. In the UK job market, the reality is more practical and more encouraging for career switchers: robotics is already embedded across manufacturing, logistics, healthcare, agriculture, defence, construction & inspection. That means there are real jobs for people in their 30s, 40s & 50s who bring operational experience, delivery skills, quality discipline & the ability to work with real-world systems. This article gives you a clear UK reality check on robotics careers for career switchers: what roles genuinely exist, which paths are most realistic, what skills employers actually hire for, how long retraining tends to take & whether age is a factor.

How to Write a Robotics Job Ad That Attracts the Right People

Robotics is moving rapidly from research labs into real-world deployment. Across the UK, robots are now used in manufacturing, logistics, healthcare, defence, agriculture, autonomous vehicles and service industries. As adoption accelerates, demand for skilled robotics professionals continues to grow. Yet many employers struggle to attract the right candidates. Robotics job adverts often receive either very few applications or large numbers of unsuitable ones. Experienced robotics engineers, meanwhile, routinely skip adverts that feel vague, unrealistic or disconnected from how robotics systems actually work in practice. In most cases, the problem is not the talent pool — it is the job advert itself. Robotics professionals are systems thinkers. They care deeply about constraints, integration and real-world performance. A poorly written job ad signals weak technical understanding and unrealistic expectations. A well-written one signals credibility, seriousness and a mature robotics programme. This guide explains how to write a robotics job ad that attracts the right people, improves applicant quality and positions your organisation as a credible employer in the robotics sector.

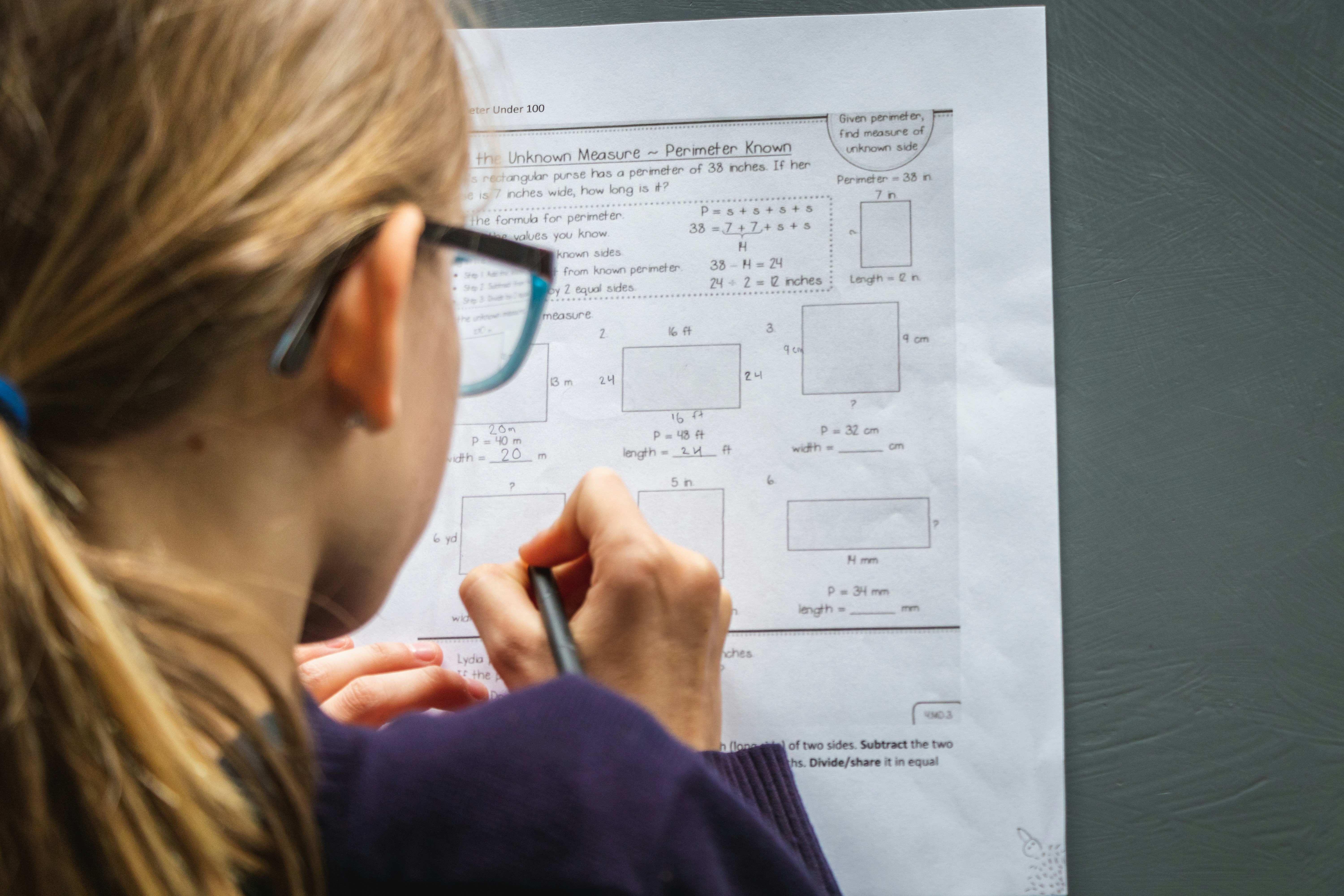

Maths for Robotics Jobs: The Only Topics You Actually Need (& How to Learn Them)

If you are applying for robotics jobs in the UK it is easy to assume you need degree level maths across everything. Most roles do not work like that. What hiring managers usually mean by “strong maths” is much more practical: you can move confidently between coordinate frames you understand rotations without getting lost you can reason about kinematics, control, uncertainty & optimisation you can turn that maths into working code in a robotics stack This guide focuses on the only maths topics that consistently show up across common UK roles like Robotics Software Engineer, Controls Engineer, Autonomous Systems Engineer, Perception Engineer, SLAM Engineer, Robotics Research Engineer, Mechatronics Engineer & Robotics Systems Engineer. You will also get a 6 week learning plan, portfolio projects & a resources section so you can learn fast without drowning in theory.